301 Moved Permanently

Few industries have grown as rapidly in recent decades as the solar photovoltaic industry, with dramatic improvements in technology, levelized cost of energy and scale of deployment. PV tracking systems can further improve the sustainability of PV power plants by creating more energy with lower lifecycle environmental impacts.

Tracking systems follow the sun’s movement throughout the day, enabling PV modules to capture more available sunlight, resulting in energy gains of approximately 10%-24% in tropical and sub-tropical regions.

Continuous technology innovation will be required to further accelerate PV deployment, and eco-efficiency can be a guiding principle for sustainable innovation. Eco-efficiency is a sustainable development principle that was established by the World Business Council for Sustainable Development in the 1990s. Eco-efficiency is defined as creating more value with less impact. In other words, eco-efficiency encourages low-impact growth.

In the case of PV, eco-efficiency translates to producing electricity at a low cost and with low environmental impacts. Eco-efficient strategies are needed to improve the affordability of PV systems while maintaining their standing as a source of clean energy. The application of eco-efficiency principles to PV systems is illustrated with a case study of PV tracking systems - specifically, utility-scale PV arrays utilizing a single-axis horizontal tracking system.

Our analysis is necessarily based on operational experience with our own tracking systems, which feature a distributed actuation architecture designed to deliver very high reliability (>99.99% mechanical availability). In our experience, distributed actuation reduces the potential energy impacts of single-point failures and is more cost-effective to install and maintain than systems using a conventional “ganged” tracker architecture. For example, the power loss associated with a single-point failure is approximately 5 kW for our tracking systems, compared with more than 200 kW to 500 kW for conventional tracking systems.

Follow the money

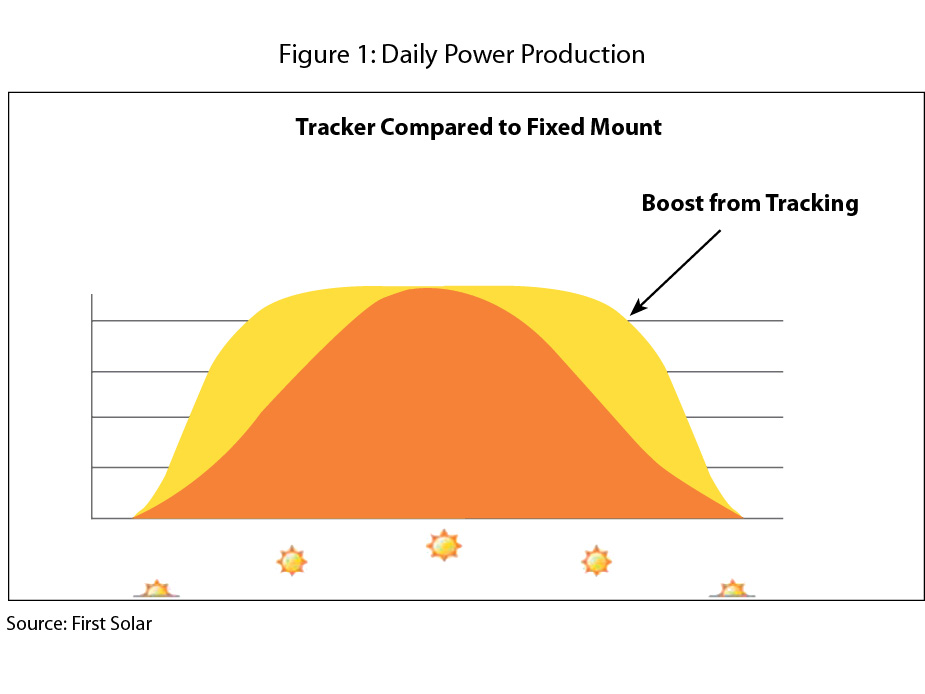

Tracking systems provide the benefit of boosting the plane of array irradiance and, consequently, the specific yield (kWh/kWp/yr) of PV systems - therefore requiring fewer modules and associated balance-of-systems (BOS) components per kWh produced compared to fixed-tilt systems. This benefit has economic and eco-efficiency consequences throughout the PV system lifecycle, with fewer modules and BOS components manufactured upstream and decommissioned downstream per kWh produced. Figure 1 shows a comparison of daily energy production curves with tracking versus fixed-tilt systems.

These benefits are offset to a varying degree by the addition of actuation and controls equipment and wiring that tracking systems require. Tracking systems also consume some electricity during operation. However, their energy yield advantage more than compensates for the higher construction and operations and maintenance (O&M) costs and their associated environmental impacts.

In order to be eco-efficient, the benefits of tracking systems must outweigh their additional requirements. This balance has been evaluated with lifecycle assessment (LCA), which considers the material and energy requirements of PV systems across the product lifecycle. Lifecycle stages include PV module manufacturing in our Malaysia production facility, BOS for utility-scale deployment in the southwest U.S., and end-of-life module collection and recycling in our U.S. production facility. Lifecycle metrics include carbon footprint and energy payback time (EPBT), which is the time required for the system to generate the same amount of energy used to produce it.

The LCA carbon footprint of our utility-scale systems in the southwest U.S. range from 16-17 g CO2e/kWh, compared with over 750 g CO2e/kWh for the average U.S. grid. The EPBT ranges from 0.6-0.7 years over a typical 25-year system life. Lifecycle impacts for tracking systems are slightly (1%-3%) lower than for fixed-tilt systems. BOS impacts for tracking systems are higher than for fixed-tilt systems; however, this difference is counteracted in the module and end-of-life stages.

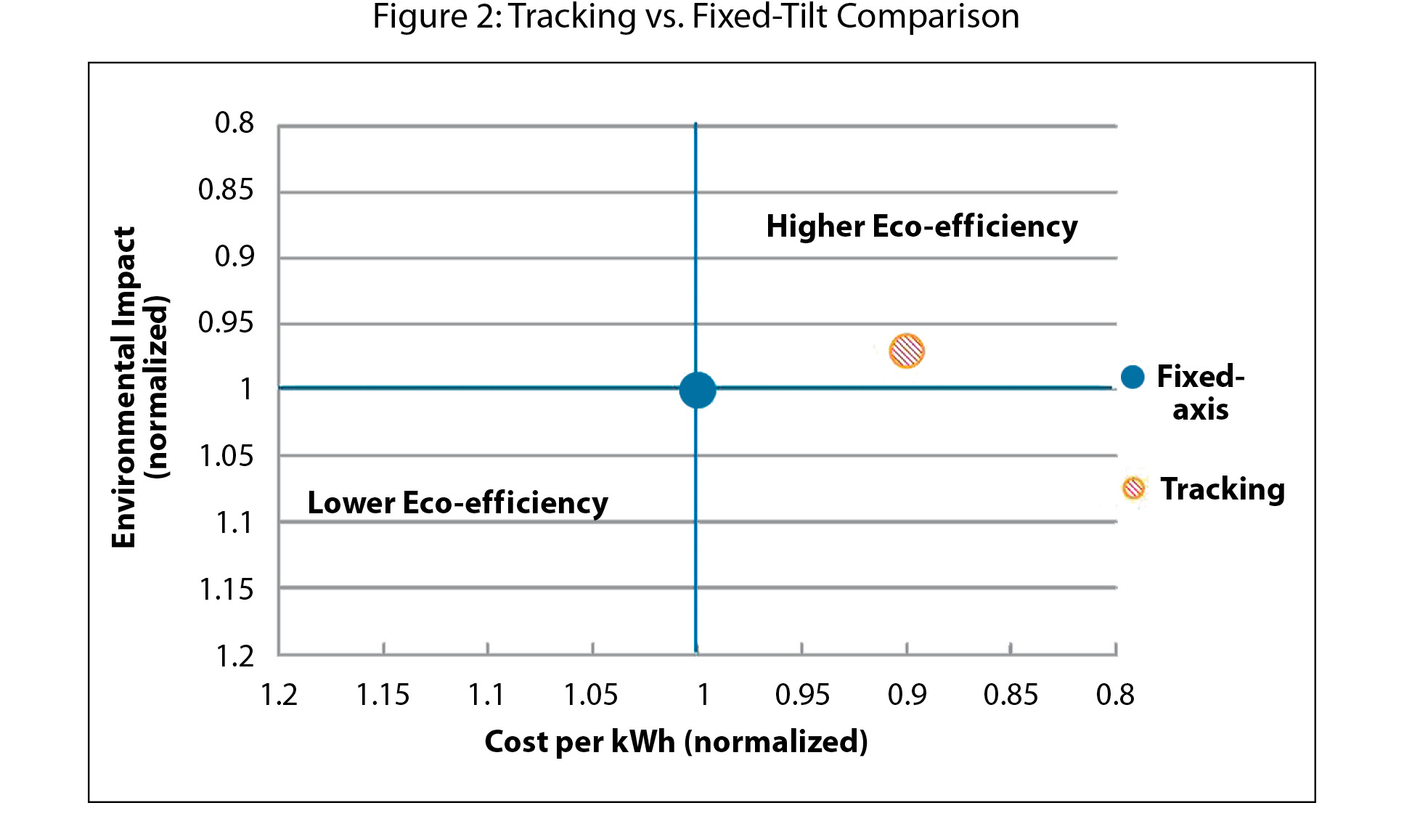

From an economic perspective, tracking systems have slightly higher construction and O&M costs per Wp-dc than fixed-tilt systems due to the incremental tracking equipment and associated cabling. However, these costs are often dwarfed by the improved specific yield of tracking systems, resulting in up to 10% lower levelized cost per kWh in the southwest U.S. case study considered here. Because tracking systems have the potential to create more value with less lifecycle environmental impact, they can be an eco-efficient strategy for improving the sustainability of PV systems.

Figure 2 shows the eco-efficiency of the First Solar Tracker compared to First Solar’s fixed-tilt utility-scale PV systems in the southwest U.S.

Face the energy

A key factor influencing the eco-efficiency of trackers is the incremental energy generated from tracking, compared to an optimally designed fixed-tilt system. Tracker energy gain (TEG), defined as the increase in kWh per kWdc, is site-specific and can vary from 10% to 25% for a single-axis horizontal tracker. The two key drivers of TEG are latitude and the ratio of diffuse horizontal insolation to global horizontal insolation (%DHI).

The effect of site latitude on TEG is straightforward; the lower the latitude, the closer the sun travels to the normal path of horizontal trackers, which equates to more plane-of-array insolation collected by the modules.

The advantage of tracking systems over fixed-tilt systems is their ability to harvest more direct beam irradiance, and because high diffuse lighting implies low direct beam, it is intuitive that sites with higher (>40%) diffuse light have relatively low TEG. Trackers perform best in locations with clear sky. Fog, clouds, dust, smoke and/or other pollution contribute to a higher diffuse component and reduce TEG.

The specific cutoff for the economical use of tracking systems varies with project design and the economic value of the energy generated, which is market-specific. Therefore, no single TEG value can be determined as the threshold for economical use of tracking systems; however, this minimum value usually lies between 13%-17%.

A heat map of meteorological data, such as that provided by Meteonorm, would show global TEG variability. Green regions are likely to be favorable for deployment of tracking systems. Red regions are likely to be favorable for deployment of fixed-tilt systems. Yellow regions may or may not be favorable for deployment of tracking systems, depending on system design and the economic value of energy in those regions.

Depending on project design, site latitude and diffuse light conditions, use of tracking systems can be an eco-efficient strategy for improving the sustainability of PV systems, potentially lowering both costs and lifecycle environmental impacts per kWh generated. Eco-efficiency is a guiding principle for sustainable innovation that can further accelerate PV deployment. S

Product: Tracking Systems

Tracking Systems Boost Eco-Efficiency

By Parikhit Sinha & Scott Dailey

Tracking systems enable PV power plants to produce more energy with fewer modules, thereby lowering costs.

si body si body i si body bi si body b

si depbio

- si bullets

si sh

si subhead

pullquote

si first graph

si sh no rule

si last graph