301 Moved Permanently

Hybrid technologies involving solar power are proliferating, mostly on the microgrid scale, typically involving photovoltaic solar paired with diesel generators and storage systems. However, the concept of integrating large-scale solar arrays with other generation sources in hybrid generation projects at the utility level has been the focus of much discussion, development and even deployment for many years.

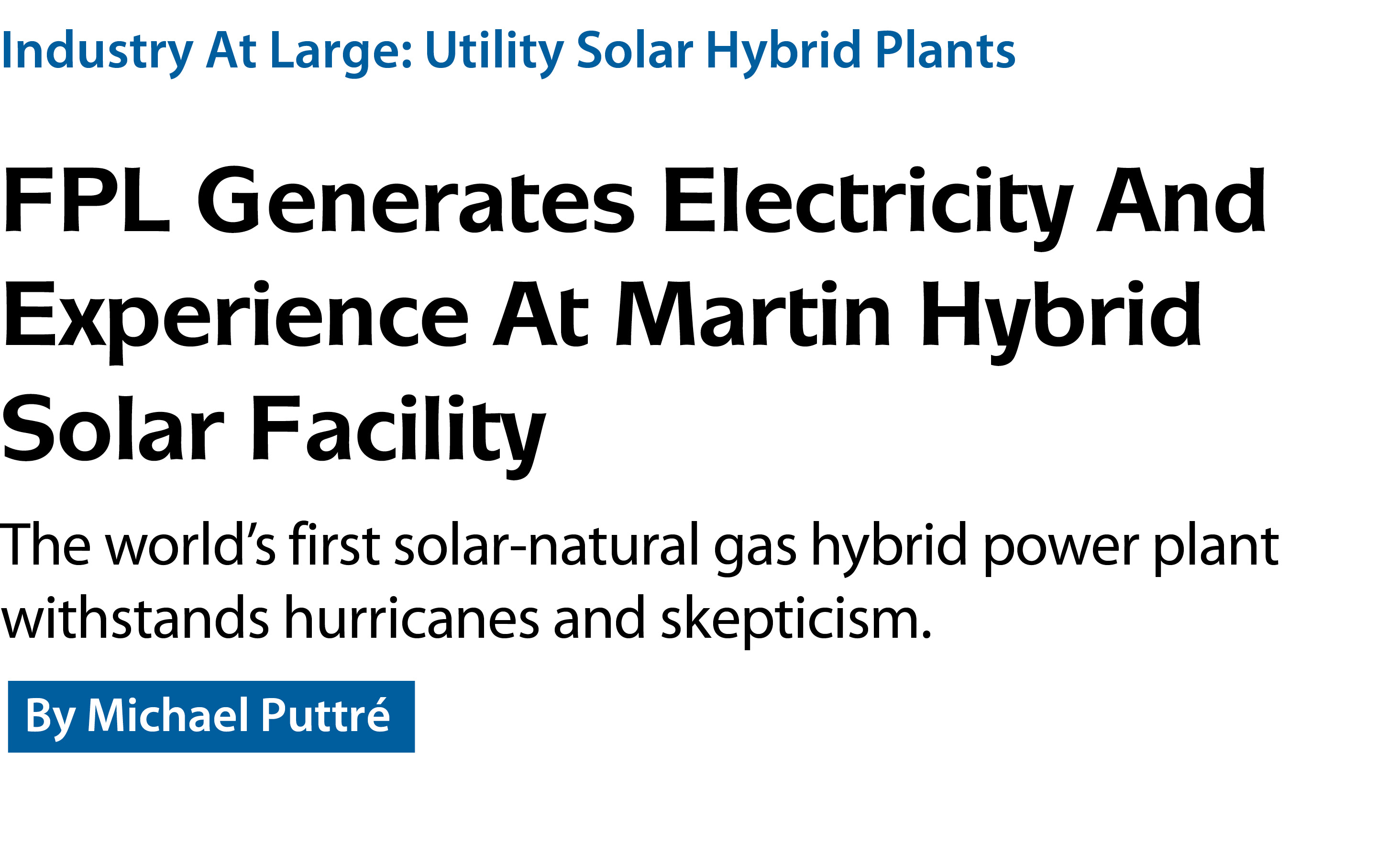

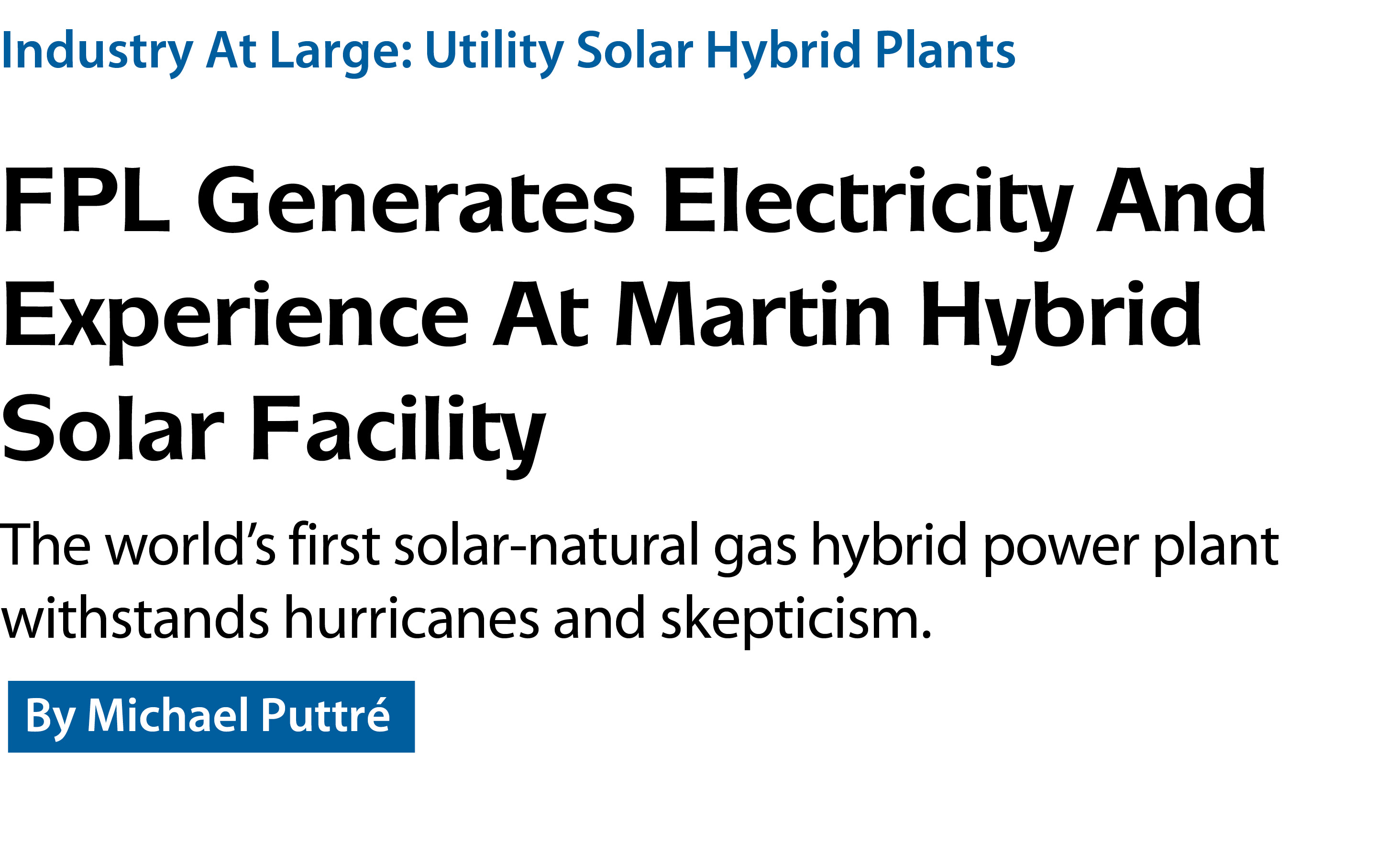

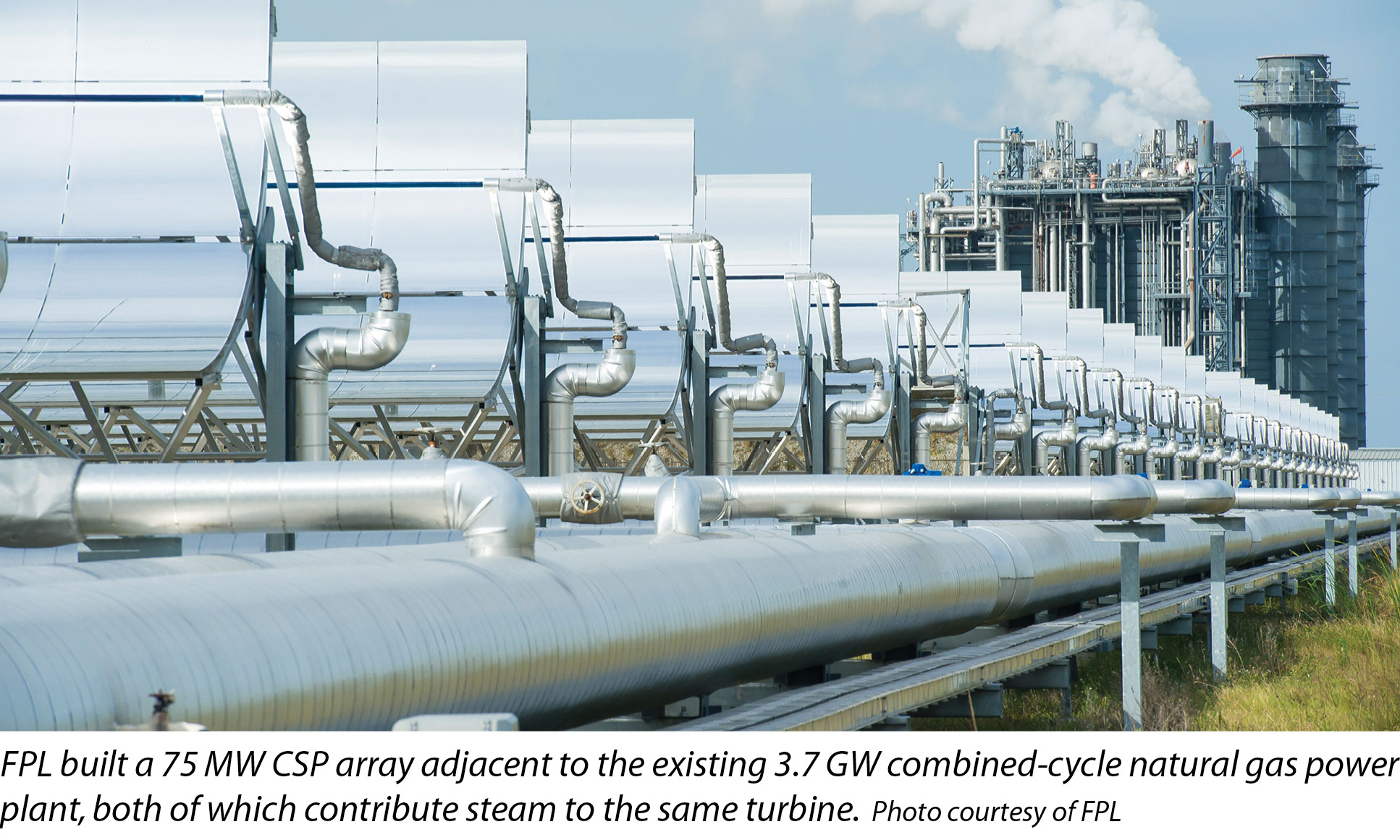

Concentrating solar power (CSP) technology, in particular, is seen as the most promising sun-powered partner in large hybrid electricity generation projects. In November 2010, Florida Power & Light Co. (FPL) commissioned its Martin Next Generation Solar Energy Center - a 75 MW parabolic-trough CSP system collocated with an existing 3.7 GW combined-cycle natural gas power plant. The solar portion, which incorporates over 190,000 large, concave mirrors spread over 500 acres, pipes steam into a common turbine that is also supplied by the gas plant. The concept is for the turbine to generate electricity from either or both of the individual generating stations on an as-needed basis, with the goal of reducing fuel consumption.

FPL describes the project as the first hybrid solar plant in the world and notes that, at the time of its commissioning, it was the second-largest solar facility in the world. Although it has been eclipsed more recently by the 392 MW Ivanpah solar tower CSP project in California and the 280 MW Solana parabolic-trough CSP station in Arizona, among others, including some large-scale utility photovoltaic power projects, it remains among the largest solar facilities on Earth.

Buck Martinez, senior director of FPL’s Office of Clean Energy, says that although the scale of the Martin CSP facility is impressive by anybody’s standards, it is its role as the world’s first and essentially only utility hybrid solar plant that makes the project important. The economics underpinning the plan’s concept and design in the mid-2000s are more difficult to justify today with the advent of very competitive natural gas prices. At the same time, Martinez says the plant remains valid as a technological and engineering success. Plus, economic conditions are nothing if not changeable.

“Speaking as a utility, I think we have to look at the economics differently than if you were looking at a stand-alone project,” Martinez says. “As a utility today, we look great because we have a very heavy portfolio of natural gas. If you were looking at natural gas prices a few years ago, we would look pretty foolish.”

Martinez says FPL is always looking at ways to balance its portfolio of generating assets and to diversify the fleet. The utility has nuclear and natural gas as the primary producers. However, FPL has announced that it is going to build three new 75 MW solar power projects, although these will be PV.

“We love solar,” Martinez says. “It’s an opportunity for us to be able to diversify our portfolio. In some cases, on a project-to-project basis, you might have some economic disadvantages. But, in the event that gas prices go up, solar is a nice hedge.”

The question at hand, though, is whether utility-scale solar hybrid power generation has a future.

Steam-powered

The Martin facility is a true hybrid in the sense that it consists of two completely independent generating assets: the CSP array and the Unit 8 natural gas-fueled plant at the Martin site. At the same time, the independent generators share the same means of producing electricity - in this case, a steam-driven turbine.

The key component of the parabolic-trough CSP system is the heat-transfer fluid, which is run through tubes at the focus of the concave mirrors. The fluid enters the solar steam plant, converts water to steam, then cycles back through the solar fields. As an early adopter of the technology on such a large scale, FPL found itself exposed to the usual teething problems and the bad press that goes with them.

“The first year, we had a spill,” Martinez says, referring to a release of a reported 46,000 gallons of Dowtherm heat-transfer fluid into the environment after a pressure buildup in June 2011. “Obviously, we made some changes there. A lot of the challenges that we initially had were not so much related to the technology, but the innovation of combining the two assets.”

Although Martinez says the project has taken a lot of heat, it comes with the territory of pioneering a new technology. But by the same token, he says it has propelled FPL into the forefront of Florida’s solar sector.

“Some of the characteristics of working with a hybrid plant are that a lot of the lessons we learn are not just related to solar,” Martinez says. “We’ve learned a lot of stuff on the combined-cycle side that we can apply to the CSP facility and vice versa. The same people who manage the gas plant manage the solar plant. There’s a lot of interchangeable intellectual parts there.”

Martinez says it is this philosophy of continuous improvement that has kept the Martin hybrid facility productive and on track to serve out its projected 30-year service life.

“In essence, you are at the mercy of each other,” he says. “When Unit 8 is down for outages, or what have you, it affects the solar project. I think it is fair to say that we have done a lot better synchronizing. We continue to learn. But we’re very bullish on it.”

It would help the learning process if more hybrid CSP-natural gas plants were built. This would be helpful both in terms of generating more expertise on their design, construction and operation, and also on supporting the industrial base, which would bring costs down. As the Martin center is essentially the only such facility in existence anywhere, Martinez says they get a lot of visitors. This is a source of pride.

“Overall, we are very pleased with the performance,” he says. “I think we are going to continue to make improvements as we go along.”

At the same time, Martinez says FPL takes a fleet rather than a project approach to its electricity generation assets. The utility is in the power generation business, not the technology innovation business. The first mission of the Martin Next Generation Solar Energy Center is to generate electricity to sell to ratepayers.

“For the Martin center to have a twin or a son or a daughter, I think you are going to have to look at the economics,” Martinez says. “At the end of the day, I think the technology is great. But, we always have to go to our public service commission to get our projects approved. Solar is solar, and electricity is electricity. They want reliability and lower cost. If it doesn’t fit into that mantra, it’s tough to get them approved.”

By one definition, the Martin facility may not be an orphan for long. Last year, Enel Green Power started construction of a 17 MW parabolic-trough CSP plant to operate alongside the existing 33 MW Stillwater geothermal power station in Nevada. The Stillwater geothermal plant, consisting of two binary-cycle units, will be integrated with the CSP system so that they contribute to the same turbines.

Enel says the CSP project is aimed at testing a new technology and determining how best to integrate it with a geothermal binary plant. The CSP system heats tubes of pressurized water. The integration work will enable the CSP component to raise the temperature of the geothermal fluid extracted from the wells to improve the cycle’s yield and increase its electricity output.

Using parabolic-trough technology with demineralized water under pressure as the working fluid, Enel expects the CSP plant to increase production by about 3 GWh per year, which will be sold to NV Energy through the existing 20-year power purchase agreement.

Other combinations are possible. A consortium set up between India and the European Union is developing a 3 MW CSP biomass hybrid power plant in Bihar, India. The so-called Scalable CSP Optimized Power Plant Engineered with Biomass Integrated Gasification (SCOPE-BIG) would make use of abundant biofuel resources to produce high-temperature steam, while the parabolic-trough CSP portion would contribute medium-temperature steam to the turbine.

Although the Stillwater and SCOPE-BIG facilities would be true hybrids in that independent generating assets would be contributing to the same turbines, it is the pairing of CSP with fossil-fuel sources that seems to have the greatest potential for utility applications.

In November 2013, the U.S. Department of Energy (DOE) announced a $10 million award to the Sacramento Municipal Utility District (SMUD) to develop a hybrid CSP and gas-fired power plant that could serve as a model for such hybrids all across the U.S. At the time, DOE officials were saying that up to 21 GW of CSP could be integrated with existing power plants.

The SMUD project was envisioned to build a 10 MW parabolic-trough CSP system collocated with its existing 500 MW Cosumnes gas-fired power plant. Although significantly smaller than FPL’s Martin facility, the CSP portion of the SMUD project was supposed to contribute direct, high-pressure steam at temperatures exceeding 1,000°F. The steam produced by the Martin CSP array typically reaches 740°F. Higher-temperature steam from the CSP portion of a hybrid means the natural gas portion can use less fuel.

“Small” hybrid CSP could be shoehorned into locations with existing plants in populated areas where space is at a premium. The DOE says the CSP portion might provide an average of 5%-10% of the steam for the cogeneration facility. Nevertheless, this would produce a commensurate reduction in the amount of fossil fuels consumed.

However, it is unclear at this point whether SMUD is going to move forward on the project beyond the evaluation stage. The decline in the price of natural gas may have made the project uneconomical. The DOE does not have any new hybrid funding planned.

Undaunted, the DOE last October set aside $25 million in new funding to advance CSP system technologies. The grant program is intended for research and development projects to improve the performance and increase the efficiency of CSP plant components. In particular, the DOE says it hopes to spur efforts to overcome efficiency and temperature limitations in solar collectors, receivers, thermal energy storage systems, heat-transfer fluids and other technologies.

Martinez agrees that the economics of energy generation currently make it a difficult sell. Moreover, in his opinion, the economics of hybrid CSP are more favorable toward the larger end of the scale. Smaller is more difficult, he says, because on a cost-per-kilowatt basis, it is harder to justify, particularly with natural gas prices so competitive. Building larger plants in a systematic way is one strategy to reduce soft costs.

“I think it is a great technology,” Martinez says. “I think there are going to be great applications of this technology in the future. But until you start to see PV going back up again, it’s going to be tough. For whatever reason, the DOE has really pushed hard on the dollar-per-watt for PV. But as much as we have had conferences and stuff on the hybrids, they haven’t launched a ‘man on the moon’ initiative.”

In addition to natural gas prices, the CSP segment of the solar sector seems prone to PV envy. Martinez reports that the parabolic trough technology with an oil-based heat- transfer fluid has worked well for the Martin facility. Part of the challenge on the CSP side has been the proliferation of PV. Because of the scale of its market penetration, the cost of PV has come down.

“When we built Martin, the CSP technology was actually cheaper than PV on a per-kilowatt basis,” he says. “If you were to have the same adoption rate and proliferation, then you would begin to see a lot more innovation because you would be building a lot more and get a lot more experience in the construction of it. Just like we have been learning a lot about the PV side.”

Solar vs. Florida

One key area of expertise FPL is developing with the Martin center is in the area of operating hybrid solar plants in the so-called Sunshine State.

“We understand a lot better now the dynamics of the Florida climate, which is a challenge,” Martinez says. “Typically in summer, we have a lot of cloud coverage here with rain, so we depend a lot on Unit 8. Days that are nice and sunny, we get a lot of production from the Martin solar project.”

The local environment contrasts with the CSP center of the U.S., the deserts of the Southwest. Florida does not have much of a problem with dust, and the frequent rains wash the mirrors without any special attention or expense required. The flip side of this is that the Martin site is subject to a tremendous number of lightning storms of sometimes frightening intensity.

Weather monitoring is an important activity in operating the Martin center efficiently. Because of Florida’s exposure to hurricanes, FPL already had developed and incorporated a sophisticated weather monitoring system into its operations. Also, the likelihood of hurricanes factors heavily into the Martin center’s design and construction. The solar array is able to sustain winds of up to 140 mph.

Martinez says, “We have a lot of structure - cement and steel - on this facility. They’re not going anywhere. The real fear is flying debris.”

The concave mirrors are equipped with trackers, which is a necessary component for a CSP system. The trackers enable the mirrors to be stowed upside down, with the focus of the concave mirrors pointed at the ground. This helps with wind loading. In addition, the mirrors are flexible.

“Because of the hurricane issues here, you could stand and jump on these mirrors,” Martinez says. “They also are somewhat malleable. They are very different from the flat mirrors you would use in a CSP tower facility in California.”

Ultimately, Martinez says the utility solar hybrid concept has proven itself as a technology and would have proved itself economically if the energy market conditions that existed at its conception were in place today. The fact that they are not is a challenge. However, who is to say that fossil fuel prices will continue to decline? Natural gas prices, in particular, have held steady as rising supply meets rising demand.

The technology, he says, is fairly basic. You are heating a fluid with mirrors and making steam. That works fine. What he would really value is the opportunity to build a lot more utility solar hybrids as an industry because it would provide the opportunity to collectively work on new concepts from the plant level - how you design them better and how to approach construction so as to capitalize on Six Sigma and industrial engineering techniques.

“I think, in the short term, there are regions in the world where you have sunny climates and higher prices for electricity,” Martinez says. “Look, there’s going to be a day when these things are going to hunt.”

Industry At Large: Utility Solar Hybrid Plants

FPL Generates Electricity And Experience At Martin Hybrid Solar Facility

By Michael Puttré

The world’s first solar-natural gas hybrid power plant withstands hurricanes and skepticism.

si body si body i si body bi si body b

si depbio

- si bullets

si sh

si subhead

pullquote

si first graph

si sh no rule

si last graph