301 Moved Permanently

Today’s residential and small commercial solar photovoltaic inverter marketplace includes a myriad of solutions and choices, from micro-inverters for each module to single-phase and three-phase string inverters. These products are expected to operate in electrically and environmentally harsh environments, with service lifetimes that can approach and exceed 20 years.

The PV inverter landscape is also marked by many new entrants and products from established industry players. These dynamic market characteristics increase the importance of thorough due diligence in the inverter selection process. An additional complexity is that the inverter product data sheets and warranties are not standardized and present information in ways that are often challenging to compare. Independent third-party data can be very beneficial in choosing the optimal inverter solution.

To date, solar inverter products in North America have been evaluated for interconnection integrity (IEEE 1547) and compliance with the governing safety standard (UL 1741). Some regional jurisdictions have required additional tests for interconnection conformance. However, from an industry perspective, comprehensive solutions for screening inverter products in terms of performance and long-term reliability fall short. Inverter qualification testing for performance and reliability can add significant confidence when selecting a specific inverter product.

With these facts in mind, DNV GL has identified and developed advanced testing methodologies that blend performance and reliability tests to better support inverter selection practices. This benchmarking approach gives owners, operators and developers the information needed to make informed decisions regarding inverter expectations, lifecycles and energy yield.

Beyond the data sheet

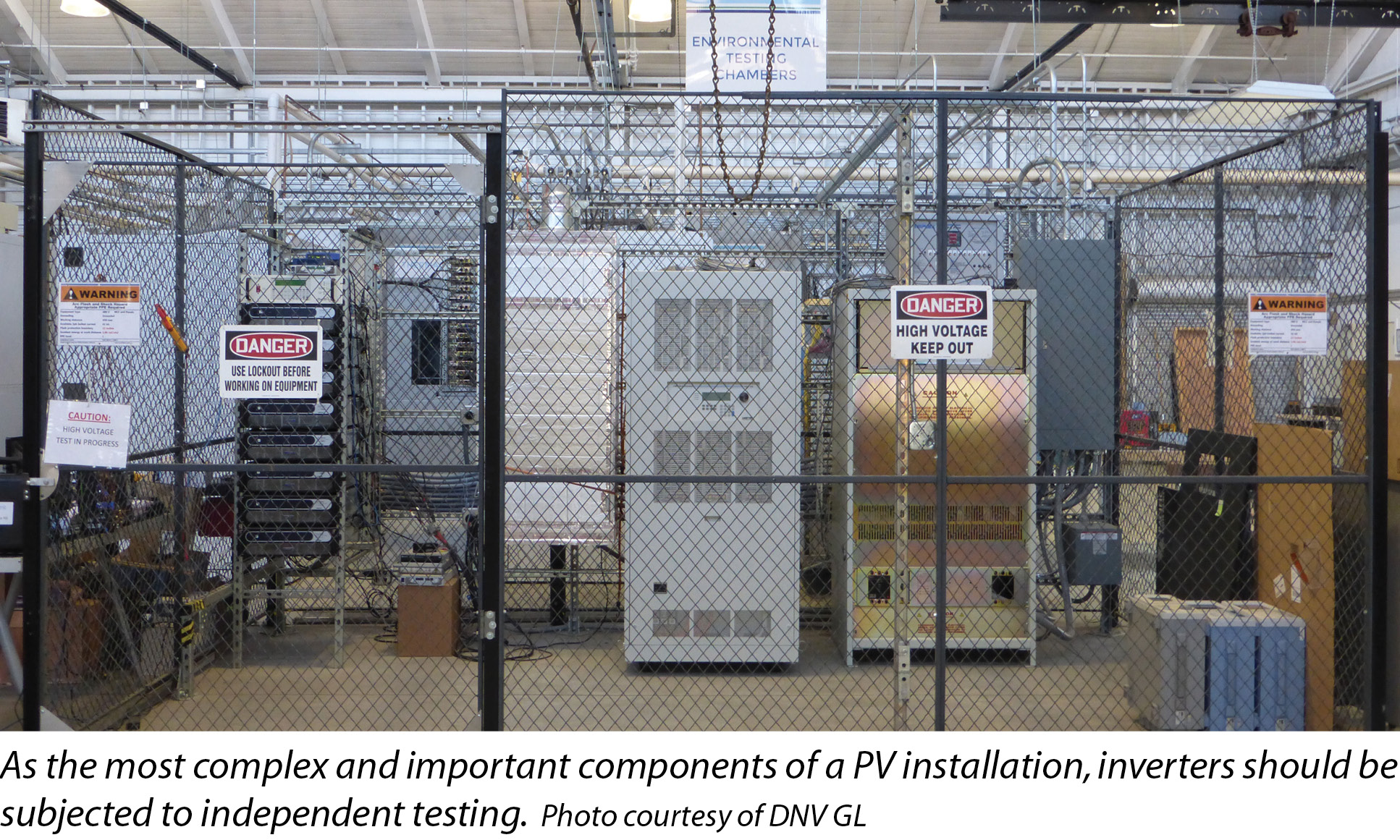

As a critical part of PV systems, PV plants and, ultimately, PV portfolios, the inverter is the most complex component and has the key function of interfacing the solar power from the PV modules with the utility grid. Inverter issues have historically contributed a significant portion of system downtime and service issues.

From a reliability perspective, the downward cost pressure has led to design trade-offs by manufacturers in the areas of component selection and system de-rating. The expanding need for inverters to become utility grid stewards by assisting during transient events can lead to similar reductions in the overall product design margin. Common examples include increasing the AC and DC operational envelopes of the inverter, further stressing the internal components and subsystems.

On the performance side, inverter products vary greatly in their efficiency, their ability to track the maximum point of the array, how they handle high DC-to-AC power ratios, and how they operate over their stated temperature and voltage envelopes. Manufacturer data sheets often list operational bounds that cannot be realized in the field. These factors can lead to reduced system availability and underperformance over the operational lifetime of the PV system.

An inverter qualification testing strategy should combine laboratory and field testing to provide a comprehensive approach toward better documenting product performance. The test sequence should support a comprehensive analysis that spans five essential areas of inverter operation.

These five key levels of testing include the following:

- Functionality - Will the inverter operate?

- Safety - Will the inverter be operated safely in the field?

- Performance - Will the inverter perform as expected when connected to a solar array?

- Robustness - Will the inverter meet the expectations in a real-world field application?

- Reliability - Will the inverter last without requiring excessive maintenance?

Our lab testing sequence makes use of dedicated equipment, including PV array simulators, grid simulators and environmental chambers. Under such a testing regime, inverters are subjected to aggressive operational conditions, while research-grade monitoring equipment is used to track electrical “health” signals and device performance. The field testing provides a validation of the laboratory data while showing device response in a real-world, “under sun” environment when connected to a PV array.

A reality-based sequence

In recent years, the International Electrotechnical Commission (IEC) 62093 working group has made significant progress in developing testing methodologies that stress PV inverter products to better categorize reliability of the full systems. These testing techniques aim to provide a uniform set of stressors to the inverter products that are defined by output power ratings and typical installation environments. The categories of the inverter products then define the bounds of the test stressors, whereby existing IEC standards are referenced for testing adherence where appropriate.

DNV GL developed its inverter reliability testing sequence based on the findings and insights from the IEC 62093 working group. The testing sequence allows for inverter products to be compared or benchmarked with regard to their relative operations under these controlled environments. The draft standard further defines differing classes of product failures - ranging from safety-related failures to errors in the reported inverter data sets - in order to better categorize product robustness and provide critical data. This approach, allowing for insights into inverter product robustness and resiliency, offers developers, system owners and site operators additional information for making supply chain and inverter product decisions.

Discussions of inverter performance are increasingly associated with interconnection requirements, installation conditions and operational constraints. As a practical matter, the North American market has high regard for the California Energy Commission efficiency rating as a primary driver for inverter performance comparisons. Although this number does provide a uniform comparison of inverter products, it is but one measure of performance.

For many residential and commercial installations, maximum power point tracking (MPPT) efficiencies; resilience to false trip events, such as series arc faults or ground faults; and operation across the DC voltage and stated ambient temperature profiles are equally important from a total energy harvest perspective.

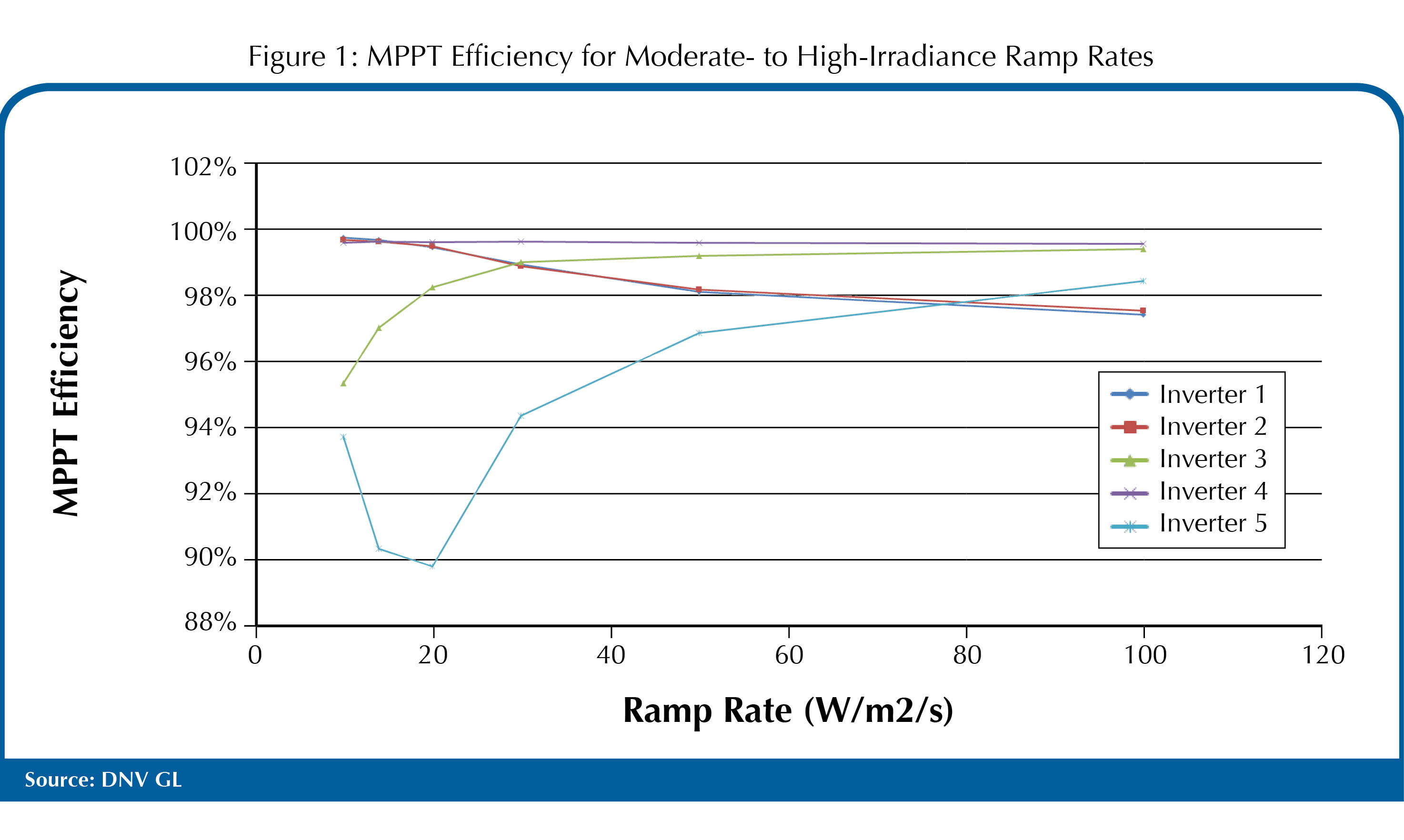

Figure 1 highlights differences in commercially available inverter products to track dynamic maximum power points as functions of changing irradiance. This graphic is meant to illustrate how similar products produce significant differences in energy harvest depending on changing irradiance conditions. Our performance testing sequence incorporates device operations with regard to temperature and to AC and DC voltage. Together, these testing sequences promote a deeper understanding of expected lifetime energy harvest performance.

Residential single-phase string inverters and commercial three-phase string inverters are offered by manufacturers with a wide range of specifications. Some purchasers of PV inverters view these products as commodity items; however, this is not reflected in actual field experience. There are important differences in specifications and performance that differentiate these products from each other and affect their application to a specific project. Examples of these key elements include environmental protection characteristics, temperature ranges and de-rating, and operating voltage ranges.

It is worth noting that larger industrial and utility applications have additional operating pressures that should be reflected in a useful testing regime. The ability of such inverters to handle high DC loading ratios, react to commanded changes in real and reactive power, and adhere to specified conversion efficiencies over the range of operational conditions can greatly impact energy production and, therefore, project return on investment. For all PV power plants, inverter system performance across the three primary external stimuli - AC grid voltage, DC voltage from the PV module strings and ambient temperature - plays a critical role in long-term asset value.

Performance testing methodologies have been developed to meet the needs of project developers, owners, operators and financiers. These include adopting a breadth of existing and emerging qualification tests that comprise both laboratory and field environments to provide a better understanding of expected device performance under a host of operational conditions. As an outcome of these tests, inverter products can be directly compared - allowing for end decisions to be made based on project needs, risk appetite and total cost.

Residential Inverter Testing

Inverter Benchmarking Results In Smarter Residential Inverter Solutions

By Michael Mills-Price

PV system stakeholders need validated information beyond the product data sheets.

si body si body i si body bi si body b

si depbio

- si bullets

si sh

si subhead

pullquote

si first graph

si sh no rule

si last graph