301 Moved Permanently

Solar developers say solar carports are emerging as one of the fastest-growing segments of the market - particularly in places where getting into your car at the end of the day feels like laying tar in the hot sun.

David Froelich, director of business development for New York-based solar structure manufacturer Solaire Generation, says the idea of a solar carport is natural, when you think about it.

“Almost everyone, when they hear about the concept, says, ‘Of course. That makes total sense,’” Froelich says. “You’re turning your parking lot into a power plant, but it’s still a parking lot - and it’s a better parking lot. It’s a nicer place to park.”

The reason you don’t see solar carports everywhere - yet, at least - is because the economics of such projects work only under very specific sets of circumstances. Whatever people’s intentions are about being green, Froelich says, the overwhelming majority of renewable energy projects happen because they make economic sense. In the end, a solar canopy is essentially a very tall ground mount that requires additional materials for structure and foundation. There are also project management issues related to having an active parking lot as a construction site.

“There is no question that parking canopies are more expensive than ground mounts and rooftops,” Froelich says. “If you were to compare a 500 kW canopy project with a 500 kW flat roof installation on the same site, the latter is going to be a less expensive solution and one that is going to have higher economic returns. That doesn’t mean that canopies can’t still make economic sense for a particular project. If your threshold is an eight percent internal rate of return, you might still get there with a canopy, but then you might have gotten 11 percent on your rooftop.”

A whole new market

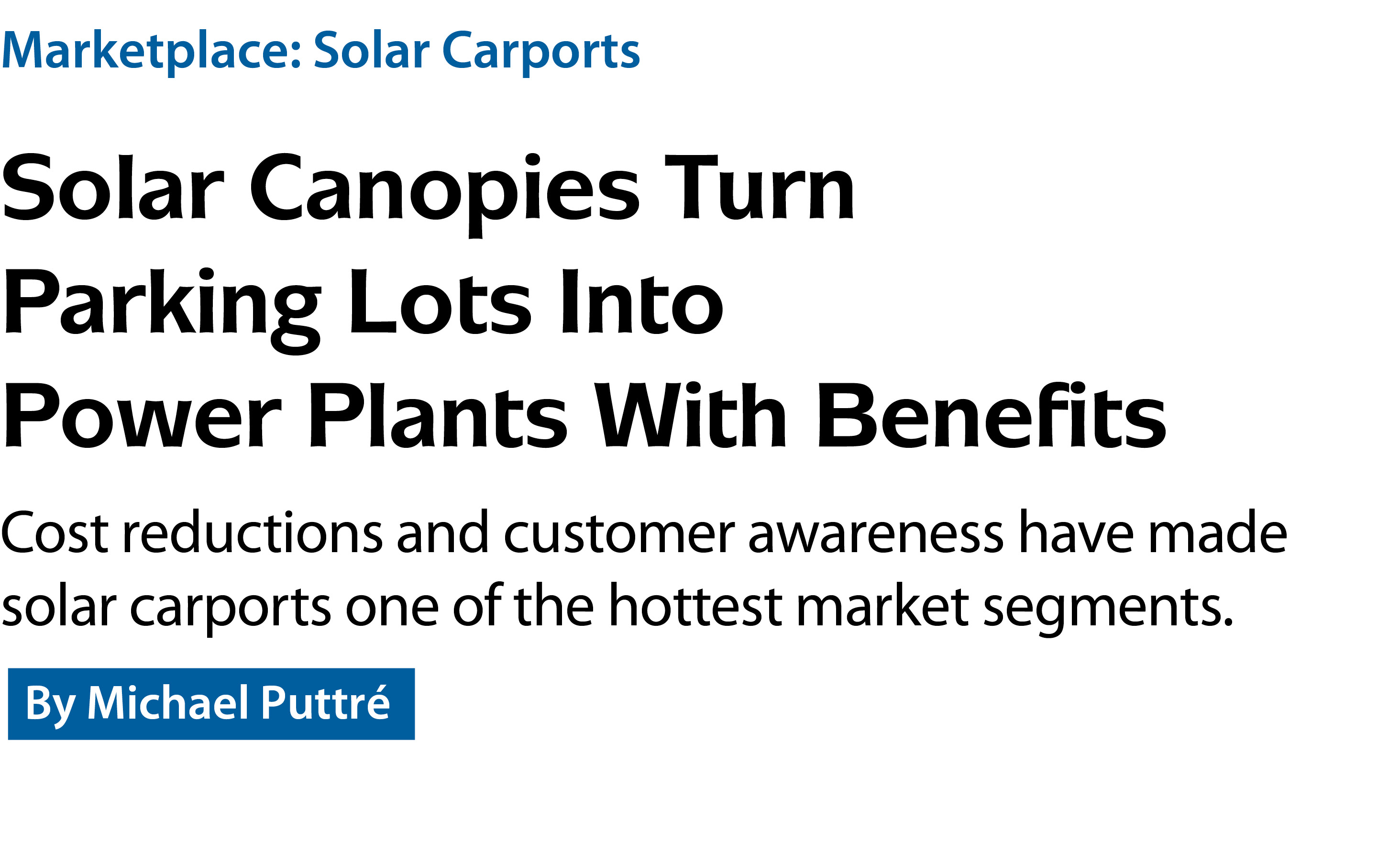

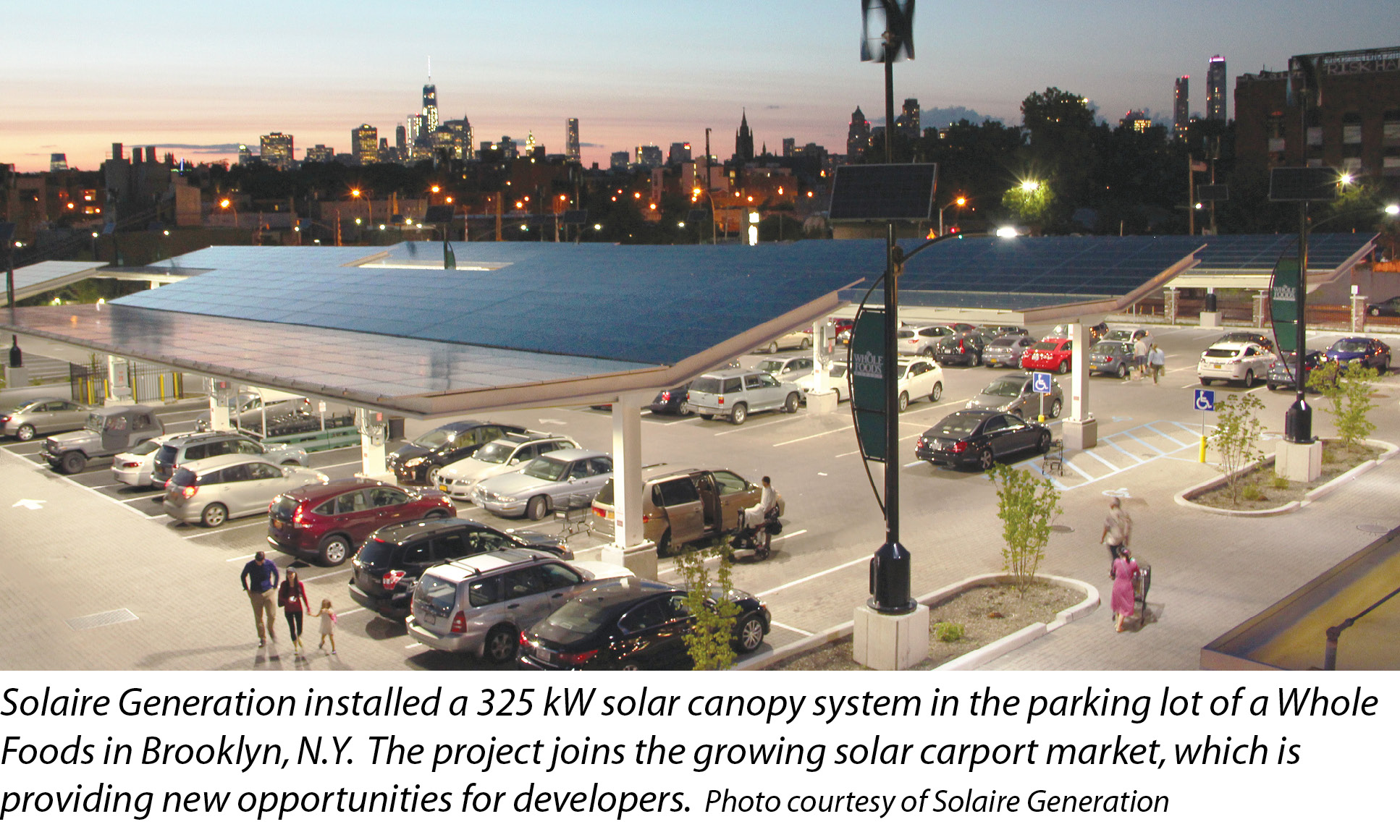

In early 2014, Solaire Generation completed a 325 kW solar carport system at a new Whole Foods Market in Brooklyn, N.Y. Working as a subcontractor for SunEdison, Solaire installed a series of double-cantilevered supports of its own design with photovoltaic panels that will supply approximately 380 MWh of electricity per year, equal to about 25% of the store’s needs.

Whole Foods was committed to taking an environmentally conscious approach to its new location, and the parking lot was the only viable option for a substantial solar installation. The rooftop of the store had been staked out for an organic garden, and the urban site had no room to spare for a conventional ground-mount array.

An interesting aspect of the site is that it overlooks the Gowanus Canal. As part of its green approach, Whole Foods decided to try to reduce water runoff from the location into the waterway. Solaire offers support for a water management system as an option on its solar structures. For this project, the water is channeled through a gutter in the center of the dual-incline canopy into downspouts in each column. The water feeds into a 30,000-gallon tank beneath the parking lot. Whole Foods is taking the “gray water” from the canopies and processing it for use in the bathrooms of the building. Another option for other installations would be to direct the water into a storm drain system.

“Our belief is that, longer term, the water is probably going to be more valuable than the electrons,” Froelich says.

Solaire’s dual-incline design of double-cantilevered canopies also deals with issues of snow and ice. Froelich says the idea was to create a structure that was sufficiently productive from a generation standpoint but would also safely direct snow and ice to the center of the canopy. “We were trying to avoid what happens to most single-tilt canopies that are built in regions with significant winter weather, which is that snow and ice build up and then slide off,” he says. “You have a 40-foot-wide canopy; that could be a 40-foot chunk of ice coming down at one time.”

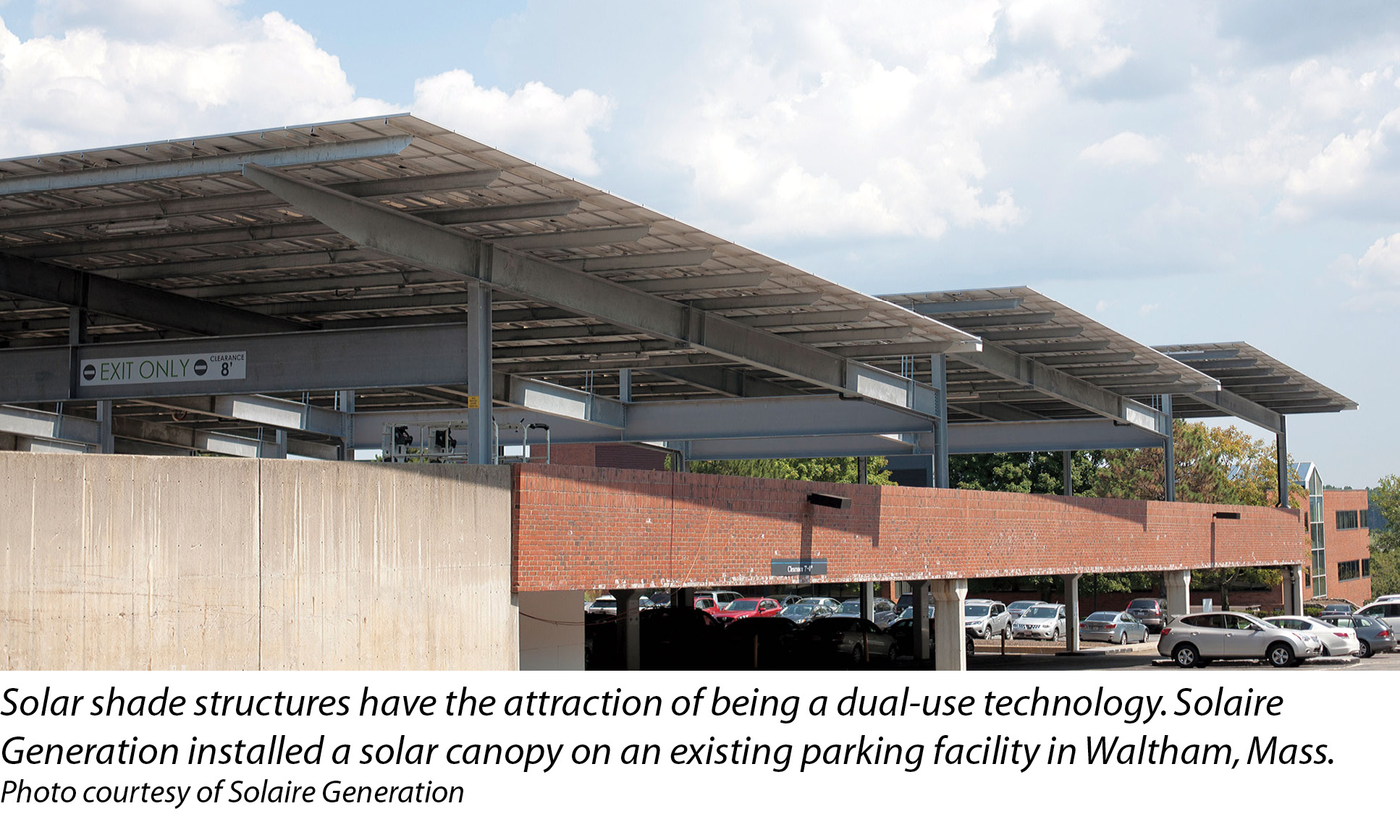

Casting a large shadow

Advanced Green Technologies (AGT) and its sister company, Advanced Roofing Inc., both based in Ft. Lauderdale, Fla., received a contract from Lockheed Martin Mission Systems and Training (LM MST) to build solar canopies for its facility in Clearwater, Fla. Clint Sockman, vice president of AGT, says that while LM MST owned plenty of acreage surrounding its Clearwater facility for a suitable ground-mount array, the local authorities encouraged a solution that did not require clearing trees and using green space for the project. Similarly, the facility had a substantial rooftop, but its various sections were in different stages of their lifecycles.

“None of them were really new enough to where a qualified solar contractor or developer would recommend putting a 25-year solar array up there,” Sockman says.

The feedback from the municipality plus the roof situation combined rather nicely with the opportunity to provide shaded parking for over 550 cars in a south Florida environment. Sockman says that this, in the end, was what made the prospect of solar canopies attractive to Lockheed Martin. “You let your black car sit out in the parking lot for eight hours and it’s not fun to climb in there at the end of the day,” he says.

AGT won the contract through a competitive bid that Sockman says rather clearly expressed the desirability of a solution based on the parking lot, although other options were not strictly ruled out. Nevertheless, in addition to designing and deploying four massive solar shade structures, AGT also has the contract to refurbish the parking lot at the same time.

Sockman says AGT builds on its origins as a general contractor in its approach to developing solar canopies. The company designs its own structures and supplies custom-fabricated steel for each installation. The 2.25 MW solar project for LM MST features four canopy structures that are each about 400 feet long and 100 feet wide. The PV components include Hanwha SolarOne modules and SunGro 60 kW string inverters. When complete, the project is expected to be the largest private, non-utility-owned solar array in Florida and is anticipated to produce 3.33 GWh of electricity per year.

Each of the canopies is a long-span truss system with four posts. Sockman says a double-cantilevered system would have had a high moment and require a lot of counterforce and weight to offset. AGT was able to engineer a system that spanned a larger area with fewer columns that reduced materials and installation costs without impacting the structural integrity of the overall system.

The foundations for the project are embedded to a depth that serves for system grounding - the array structure itself provides grounding. The structure is rated for 150 mph winds. Sockman says they had access to as-built documentation for the lot site. AGT also performs its own ground-penetrating radar survey to verify that the construction won’t interfere with any subterranean infrastructure.

The 600 feet from the canopy structures to the building interconnection posed a more significant challenge. To reduce cost and power loss, AGT uses transformers at the back of each array to step up the low voltage to medium voltage.

“We push medium voltage to another transformer, and then we step it back down to interconnect into the building because it’s more efficient to transmit electricity at higher voltage,” Sockman says. “If we weren’t stepping up and stepping down, we’d be running 12 parallel sets of 500 MCM cabling 600 feet. This way, we have one 6-inch conduit. It’s much less obtrusive.”

The entire component installation for the array is accomplished from the underside of the canopy. Likewise, most operations and maintenance services - including panel replacement - will also be addressable from the underside. The project is spaced to accommodate articulating booms in order to access the top portion of the canopy for cleaning or whatever else might be needed.

Sockman says the scale of the project enabled AGT to go large. “Now, the reality is that not every parking lot is able to accommodate a 100-foot span,” he says. “This one happened to be able to do so, and that’s the solution we provided.”

Make room for solar

Successful solar carport projects come in all shapes and sizes. San Francisco-based Vista Solar recently completed a 183 kW solar canopy system for Campbell Church of Christ and Campbell Christian School in Campbell, Calif. Cale Garamendi, sales manager and project developer at Vista Solar, says the parking lot turned out to be the most attractive place to deploy solar because of - not in spite of - the new roof the church had just put up as part of an expansion program.

“One of the rooftop sections is actually rather ideal for solar,” Garamendi says. “But the customer really was adverse to the idea of putting penetrations though a brand-new roof. They had that anxiety, even though many solar contractors like ourselves are very careful to maintain manufacturer warranties.”

Another factor was that the expansion program had left the facility with three different roof types, as well as a large number of HVAC units.

“We have a very good idea of what the projected costs would have been to add the additional engineering,” Garamendi says. “Very quickly these days, such calculations can start to level the playing field in the evaluation of parking shade structures versus more traditional options. A big part of the reason why that’s happening is that there has been a notable drop in the installed cost of the actual steel structures and concrete foundation work that is required for these structures.”

An important consideration was Campbell’s status as a nonprofit, which made the carport projects more attractive. According to Garamendi, there are a number of good options that allow nonprofits, as tax-exempt entities, to - at least indirectly - take advantage of available tax incentives. “In this particular case, we went with a power purchase agreement (PPA),” he says, adding that Vista Solar works with a financial partner that holds the PPA. “The savings amounted to a touch better than breakeven, but Campbell secured a zero percent annual escalation of its PPA rate.”

The four-carport installation features SunPower PV panels on a double-cantilevered structure. Vista Solar worked with Baja Construction of Martinez, Calif., on the design and fabrication of the carport structure. Garamendi says partners like Baja enable Vista to provide a tailored design. Although the structures cannot exactly be said to be pre-fabricated, they do have enough common components to improve the economics over a purely homegrown design.

From a construction standpoint, Garamendi says project management is always a major consideration - particularly when the site is operational. In Campbell’s case, the school has traffic for student drop-off and pick-up every day. In addition to working in a functioning church and school complex, Garamendi says there are the usual concerns when doing site work. When you’re doing a roof, you’re concerned about the roof warranty and the structure. When you’re doing a carport, you’re worried about what’s in the ground.

To do these installs, the contractors have to sink silo tubes into the ground and then pour concrete into those tubes to form the piers. For the Campbell installation, the piers were sunk about 10 feet. To avoid having to put trenches across the asphalt lot, the contractors used a directional boring machine to dig the access tunnels and lay the conduit pipe.

“The main obstacle there is that they did have quite a few infrastructure pipes, including gas pipes and sewer pipes,” Garamendi says. “We had to make sure those were identified so we could avoid them when drilling.”

John Handy, federal business development manager of California-based REC Solar, says the availability of site documentation is a key aspect of keeping the engineering cost of a solar carport project in check. REC Solar recently completed a 5 MW solar ground-mount and shade-structure system for the U.S. Department of Veterans Affairs (VA) Medical Center in Las Vegas that had been built in 2011. “In this particular site, the property was just recently built so they had a good set of drawings for the facility,” he says. “This was exceptionally helpful in locating and avoiding the underground utilities.”

Handy says the customer’s commitment is important for solar projects in general and especially so for solar carport installations, where the economics may require a bit of explanation. Nearly half of the 21 installations that REC Solar has done for the VA to date have involved solar carports.

“One reason that carports work really well for the VA is that they have a lot of hospitals that are in built-up areas that don’t have a lot of vacant land around them,” Handy says. “The carport has been an excellent way for it to bring in a solar solution while getting a second use out of a parking lot.”

Solar canopies for parking lots have advantages that go beyond purely economic considerations, Handy says. For one, many people would like to have carports with or without solar. A solar carport is not just an electricity-generating plant; it is also a value-add for the people who have to park in that lot. “If you look at it solely as a solar structure, then you start going down the road of it being a pure economic decision,” he says. “But if you look at it as a betterment for the facility, then it’s another story.”

Another aspect of solar carports is that they preserve the usefulness of the ground they occupy, which cannot be said for ground-mount arrays.

“If you put solar in a field, it’s no longer a field - it’s a solar farm,” says Soltaire Generation’s Froelich. “And it’s going to be a solar farm for 20 years, which is fine. But, it’s not a field. You put solar in a parking lot, and it is both a solar farm and a parking lot.” S

Marketplace: Solar Carports

Solar Canopies Turn Parking Lots Into Power Plants With Benefits

By Michael Puttré

Cost reductions and customer awareness have made solar carports one of the hottest market segments.

si body si body i si body bi si body b

si depbio

- si bullets

si sh

si subhead

pullquote

si first graph

si sh no rule

si last graph