301 Moved Permanently

Over the last several months, grid-tied energy storage has generated headlines and interest across the electric power sector. This attention is due to a number of factors, including U.S. Federal Energy Regulatory Commission order changes, battery pricing drops and incentives in several states. Although these new opportunities are exciting, energy storage is still a relatively new market, and project development has numerous risks.

That said, there are several commonalities between solar and grid-tied storage, and important lessons from the solar industry provide substantial guidance in energy storage applications. Performance, pricing and packaging are the “three Ps” of storage project deployment, derived from our direct experience in both solar and storage project deployment over the last few years.

Performance considerations

The first factor to consider carefully in deploying grid-tied storage is the desired or mandated performance requirements. Battery selection is a crucial factor impacting performance. Round-trip DC-to-DC efficiency of batteries varies significantly. The ancillary cooling and ambient environmental requirements for those batteries are also important factors impacting overall performance. For example, a battery may have high electrochemical efficiency but a narrow operating temperature requirement - the associated air-conditioning diminishes the net efficiency of the battery and increases operating costs. When operating models are developed, these factors need to be considered carefully.

Similar aspects relate to the inverter. An outdoor-rated inverter will not need supplemental cooling, whereas a containerized inverter will require additional cooling. The air conditioning to cool the containerized inverter will increase its operating cost and reduce its net efficiency compared to outdoor-rated models. Battery inverters also have two-way losses; they are used to both charge and discharge the battery. So any losses due to inverter inefficiency are effectively doubled in terms of net power provided by the system.

When evaluating inverter efficiency, it is recommended to use data from a variety of load and voltage conditions. Tests that have been validated by nationally recognized test labs are incredibly robust and typically require that all tests are conducted in triplicate to ensure performance and consistency.

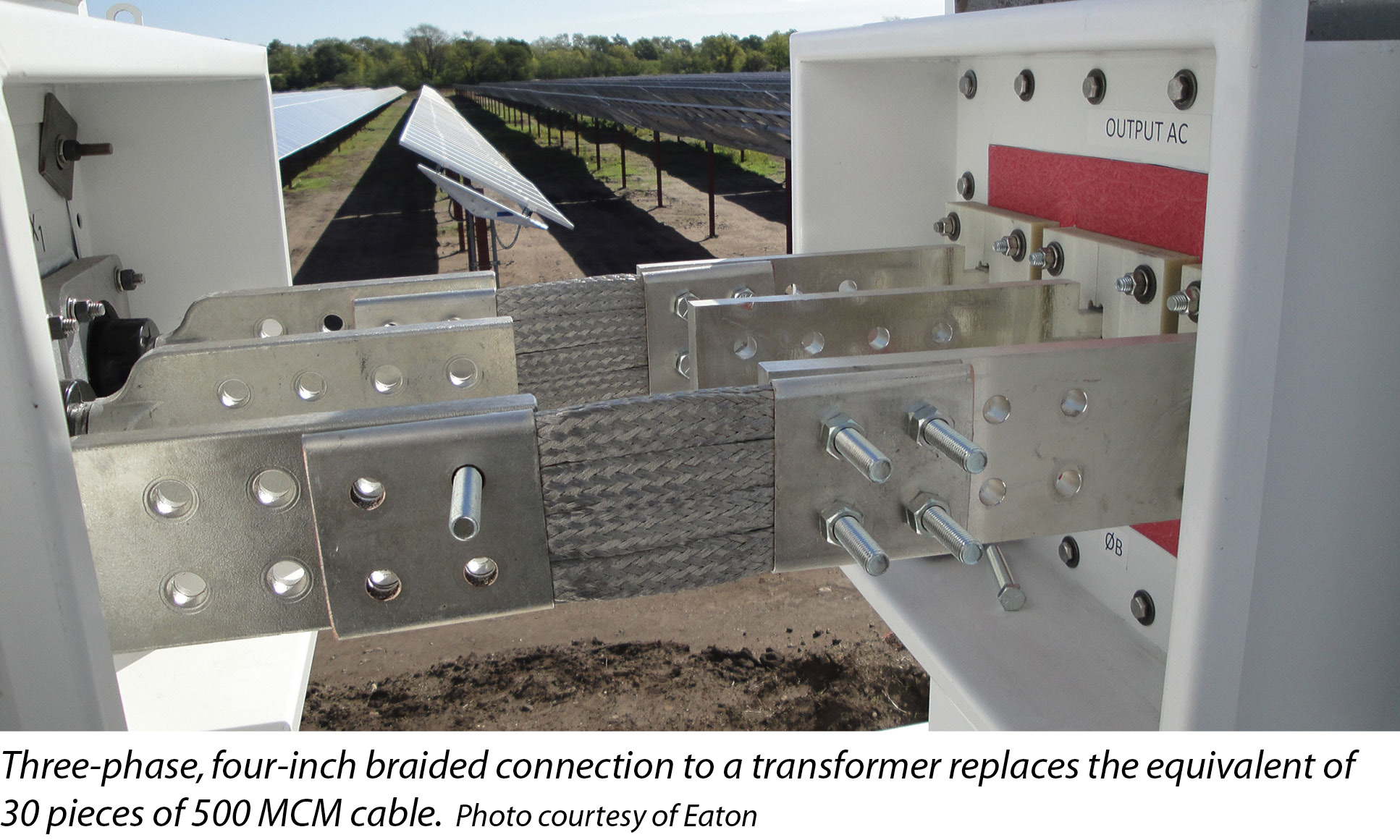

The wiring in the system is also often overlooked. Losses here occur due to power transfer over cables from one location to another. These connections should be made as short as is feasible and make use of direct bus connections, where possible. These connections offer the highest potential for both short runs and low losses.

For example, the three-phase, four-inch braided connection to a transformer may replace the equivalent of 30 pieces of 500 MCM cable. This not only improves efficiency and reliability, but also dramatically reduces installation time.

Holistic pricing

Pricing a grid-tied storage solution can be complex and should factor in the operating and maintenance costs up front. Considering these details will help a project achieve its economic goals.

Today, for example, equipment size is often not carefully factored in when developing projects and related costs. Yet, this can be important for batteries and inverters because of the amount of space they require.

As an example, a battery rated to fit in a 20-foot container instead of a 40-foot container could yield substantial savings. Starting with shipping, two containers could fit on a standard shipping truck, cutting shipping costs in half. Likewise, the cement pad base on which it is installed would be smaller and require less excavation. This also carries over to the inverter and transformer. In some cases, the financial benefits of more compact solutions are hard to determine - but in many cases, there are clear and direct savings at the system level.

Another important cost element to consider is the auxiliary power system. This system is used to provide AC power to the battery container, supporting lighting, data acquisition and environmental controls. The common approach for auxiliary power is to bring in a separate medium-voltage transformer and AC panelboard and run low-voltage AC power to the battery container.

Yet, this approach has some drawbacks. First, the medium-voltage transformer adds additional cost and takes up additional space. Likewise for the additional panelboard, cable and conduit. This approach also creates a single point of failure. Much like solar installations, newer storage inverters have auxiliary power available directly from the inverter. These are typically used to power tracking systems; however, they can also power battery containers at substantial cost savings and improved reliability.

Finally, it is important to carefully evaluate the operating cost of the auxiliary power system. Air conditioning, as an example, uses significant power, adding to the daily operating and annual maintenance costs.

Packaging matters

The next item to consider is the system packaging. Much like in solar applications, this approach has evolved over time. Early solar and storage systems often containerized the inverters and/or transformer. Though this is necessary when the equipment is only available as an indoor option, it is no longer necessary. Containerized installations struggle with a few critical issues. The first is related to proper inverter operation; inverters need unimpeded airflow for proper operation.

Containerizing the inverter often impedes that airflow. Additionally, containers tend to be quite tightly designed in terms of usable space. Working on equipment under such space constraints can be difficult and potentially unsafe. With new inverters, now rated for direct outdoor use, packaging issues can be easily avoided.

The Energy Storage Association and other industry analysts anticipate that substantial new storage capacity will be added to the grid over the next few years. By leveraging experience from large-scale solar deployments, installers can best optimize the price, performance and packaging of their energy storage systems. S

Marketplace: Grid-Connected Storage

Deploy Grid Energy Storage Using Best Practices From Existing Installations

By Chris Thompson

Designers should always keep the “three Ps”of performance, pricing and packaging in mind.

si body si body i si body bi si body b

si depbio

- si bullets

si sh

si subhead

pullquote

si first graph

si sh no rule

si last graph