301 Moved Permanently

With huge electricity needs and high irradiation levels, emerging countries, such as Chile, Brazil, Mexico and South Africa, have become significant utility-scale photovoltaic markets. These regions are eyeing solar trackers, which, thanks to attractive prices, are now considered a go-to method in the industry to achieve a better energy harvest and accelerate return on investment.

As a consequence, solar tracking companies are now crossing borders to serve these new international markets. One complication in this trend is that the newest and largest PV projects are often situated in remote areas, such as the Atacama desert in Chile. Efficient international project management has become key for each solar tracker supplier wishing to export its products. Each company has its own strategy.

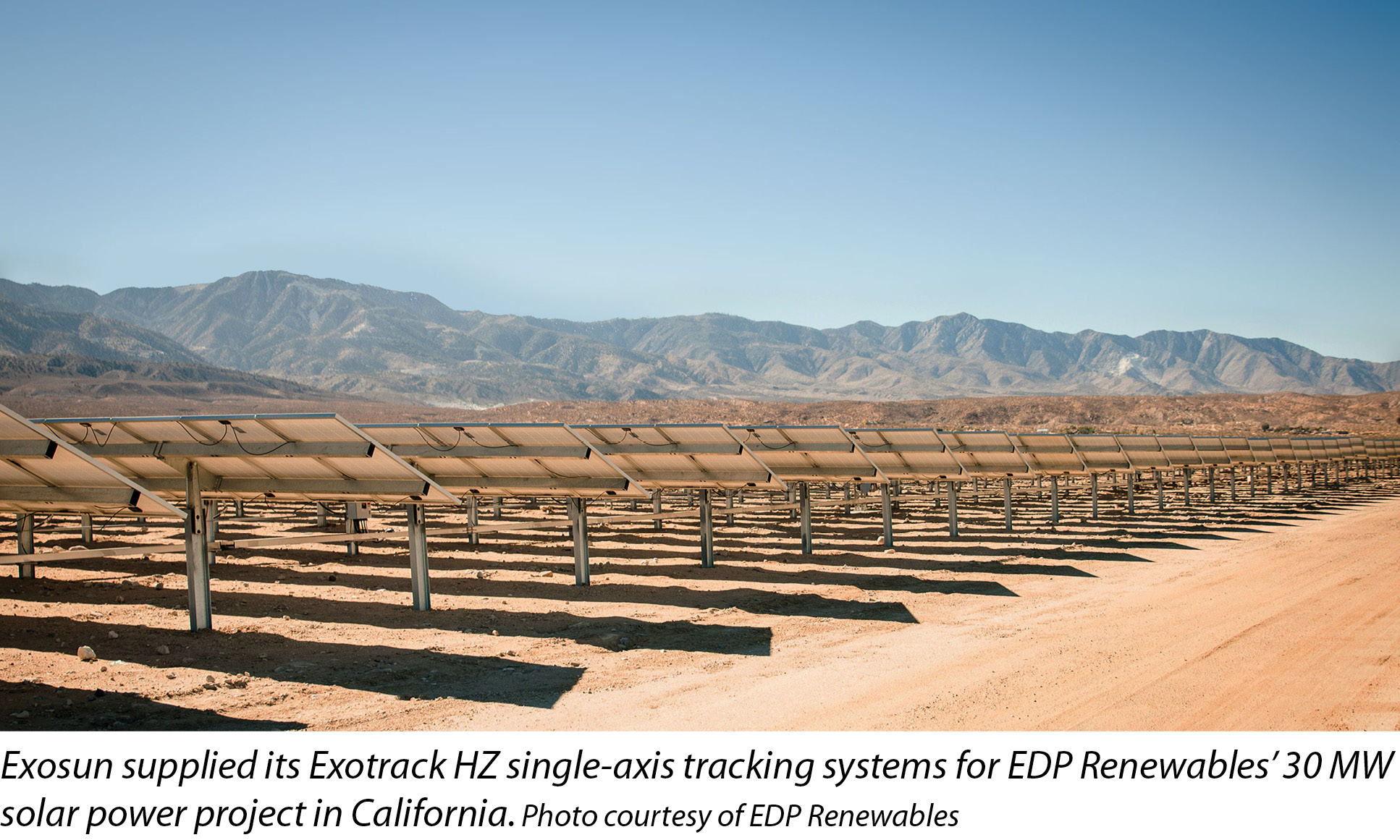

Our company has completed more than 210 MW of utility-scale, ground-mounted solar plants in our domestic market, France. In the early, immature days of the French utility-scale PV industry, we acted as an engineering, procurement and construction (EPC) company for the country’s first single-axis tracking projects. We have since sought to expand into other regional markets. With subsidiaries in the U.S., South Africa and, most recently, Brazil, we have already managed four solar tracker projects in the U.S., Chile and Mexico.

These efforts have produced some useful international project management experience that is worth sharing.

From paper to project

A number of countries, such as South Africa and Brazil, have local content requirements. In such countries, it is necessary to establish partnerships with local manufacturers and material providers. As a fabless company, we made this an aspect of our strategy, even for markets in Europe and North America that don’t have specific content-requirement rules. We routinely transfer tracker technology to qualified local component manufacturing companies.

Each regional market and customer demand is different. During the preliminary-studies phase of a project, we appoint a project engineering manager to analyze the project and prepare the best offer to the client for a strong capital expenditure optimization of the plant.

At this stage, the project engineering manager analyzes the standards that are applicable to the company’s product in the country where the solar plant will be constructed. For example, in Chile - where we are supplying tracking systems to EDF Energies Nouvelles on a 146 MW solar plant in the Atacama desert - the project engineering manager had to ensure that the product was fully compliant with the Chilean standards, which are different from the European Eurocodes and North American Society of Civil Engineers norms.

At the start of the execution-preparation phase, we assign a project manager who will be the main interface between the company and the customer through the commissioning of the plant. The project manager is responsible for overall supervision and coordination of the project and manages and minimizes project risks. He or she regularly travels abroad, as his or her presence will be required on-site at key moments of the project.

In our case, project managers are based in France, the U.S. and South Africa. They are chosen according to the project’s geographic location in order to limit travel distances and the number of time zones between the coordinating office and the customer’s site so as to optimize communications between the various stakeholders.

At this point, the project manager lists and organizes all in-house resources necessary for the execution of the project so that the administrative department can start booking flights and accommodations and submit specific visa requests for all employees required to travel abroad to the project site. In addition, the project manager sets up the construction schedule, finalizes the scope of work and coordinates with the logistician, based either in France or the U.S., appointed for the project.

The logistician prepares the project bill of materials, releases the orders and consults with the company’s certified suppliers in various countries to make sure that all tracker components arrive at the right place at the right time. The ideal is to find suppliers that are as close as possible to the project site.

The logistician indicates to all suppliers how to optimally pack the boxes and pallets containing the tracker components. He or she then organizes their transport with the selected international shipping companies. These consultations include all discussions about the most efficient combination of transportation means to deliver the product parts to the project site.

In order to closely follow up on schedules and movement, we use an advanced transport monitoring system. These logistics actions are key to keeping costs down. A break or even a delay in the supply chain can jeopardize the complete project schedule and cause significant time and money losses for all project stakeholders.

At the same time, the company’s quality assurance department prepares all documents applicable to the project and transmits them to the project manager, who coordinates all efforts. At this stage, according to the client’s needs, a project engineering manager can also be appointed by the company to offer specific engineering studies, such as execution phase reports, to ensure the optimal performance of the trackers at the plant.

On the ground

During the construction phase, the project manager remains the main point of contact for the customer, ensuring that the contract requirements and budgets are respected and applied. The logistician continues to follow up on delivery schedules with the suppliers and transport companies.

According to the services selected by the client, we can offer moderate construction support, which generally ranges from having a field technician on-site to supervise or support tracker installation up to a full integrated tracker installation package. Each country and customer has specific needs.

When full tracker installation is requested by the client, we work with certified local partners to install the trackers. As part of the certification process, the company trains its partners in the specific country on how to correctly and efficiently install its products by strictly following the company’s methodology and quality process. For example, we have certified partners in South Africa and Brazil. In the latter, we have established a relationship with a provider of solar plant EPC services.

If requested by the client, as is the case for our project in Chile, a logistician can be present at the project site to ensure optimal on-site delivery, dispatch and storage of the tracker components.

When construction is completed, the project manager - accompanied by one or more engineers, according to the project’s size and requirements - travels to the project site to commission the trackers. The commissioning process has been developed and refined by the company’s domestic project experience. Tracker commissioning mainly consists of programming the motors and the trackers’ centralized control-command system. The service may also include the development of customized interfaces and controls if the customer so wishes.

We have participated in the construction of more than 25 tracker-equipped PV plants worldwide, with several projects managed simultaneously. Efficient project management has been key to ensure on-time, on-budget delivery and installation of the company’s solar trackers without sacrificing quality.

Tracker Project Management

International Tracker Projects Have Many Moving Parts

By Gil-Arnaud Perrin

As markets for large-scale solar projects move into the developing world, strong project management principles are becoming increasingly vital.

si body si body i si body bi si body b

si depbio

- si bullets

si sh

si subhead

pullquote

si first graph

si sh no rule

si last graph